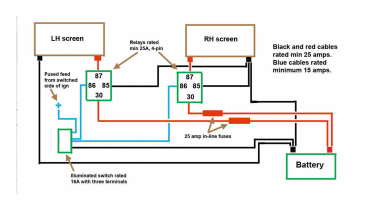

<span>Left and right-hand screens are available separately from heated </span><span class="skimlinks-unlinked">windscreens.com</span><span>. Relays, illuminated switch and fuse holder from Halfords.</span>

- Skip advertAdvertisement - Gallery continues below

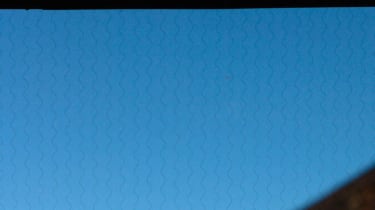

<span>The virtually invisible heated element wires run vertically with busbars top and bottom. Importantly, screens are road legal in most territories.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Disconnect the battery and remove the wiper arms. If fitted, remove the original air filter housing for access when routing the wires and siting the relays.</span>

<span>Remove the two rear view mirror screws and five large screws securing the fascia top rail. I used a screw bit and ratchet due to the limited access.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Remove both fascia end caps and undo the hidden set screws and bolts as shown here. Carefully place the heater controls out of the way.</span>

<span>Undo the fascia screws above the screen vents’ flap handles and remove the screws securing both demister vents on the top of the fascia.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Lift the fascia top rail inwards from the bulkhead and up, away from the dashboard. With any luck you won’t find any unexpected bulkhead corrosion.</span>

<span>With the fascia top rail removed, the bottom screw of the central screen finishing strip is accessed, using a magnetic screwdriver.</span>

- Skip advertAdvertisement - Gallery continues below

<span>If necessary, use a palette knife to slowly ease the finishing strip away from the old sealant. The sealant on mine had little adhesion and almost fell off.</span>

<span>Next, remove the screws holding the angled screen retainers. A magnetic screwdriver is best for the lower retainer where the screws inevitably fall out of reach otherwise.</span>

- Skip advertAdvertisement - Gallery continues below

<span>I found it easiest to gently prise up the ends of the angle strips with a flat head screwdriver before using a palette knife for the rest.</span>

<span>Take note of the spacing between the frame and the old screens, typically 5mm all round. The glass should not be touching the frame.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Pressing on the outside of the glass close to the frame, work your way around the glass until it’s free. This is easy with old sealant.</span>

<span style="font-size: 0.8125em;">Remove all traces of the old sealant. Use thinners and a Scotch pad to thoroughly clean the frame surface of any residue without damage to the frame.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Some frames have more pronounced corner welds than this one. These must not be in contact with the glass when fitted, and should be ground down if necessary.</span>

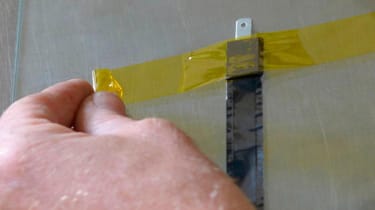

<span>Partially lift the yellow film securing the connector strips away from the edge of each screen before fitting to avoid doing so when the sealant is used.</span>

- Skip advertAdvertisement - Gallery continues below

<span>The sealing strip is applied by gently pressing it onto the frame. It’s important to keep its thickness consistent by not forcing or pulling it.</span>

<span>Apply the sealing strip to the angled finishers. I discovered that it’s better to trim any excess width before peeling off the backing. Use a sharp blade.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Rest the bottom of the screen on the aperture away from the sealant until you are happy with its position, approx 5 mm from the frame all round.</span>

<span>Once the sealing strip has grabbed the glass, it’s difficult to reposition the glass again, so take your time or you’ll have to start again.</span>

- Skip advertAdvertisement - Gallery continues below

<span>I fitted the lower angle strip first to prevent the possibility of sealant sag. Align the screw holes before letting the sealing strip grab the glass.</span>

<span>Starting in the middle, fit all the screws but don’t tighten them fully. The sealant must cushion the glass so the angled sections don’t touch the screens.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Fit the other angle finishers, always tightening the screws outwards from the centre of each finisher. All three finishers should have a similar flush fit.</span>

<span>Apply sealing strip to both edges of the central ends of the screens. I used some trimmed excess from earlier. Alternatively, apply sealant to the finisher first.</span>

- Skip advertAdvertisement - Gallery continues below

<span>If fitted, reroute the courtesy lamp wire using some sealing strip to hold it in position. Fit the finisher strip. Tighten the screws gradually.</span>

<span>Now trim any excess sealant from both sides of the frame using a very sharp blade. The sealant should come away cleanly, even in hot weather.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Next site your switch. I chose the lower dash because I prefer the illuminated switch clearly visible in use and because my lower dash isn’t perfect.</span>

<span>Wiring should following existing wires away from the bulkhead vents. This large hole was step drilled for the centrally routed positive main feeds.</span>

- Skip advertAdvertisement - Gallery continues below

Always use grommets or rubber sleeving when routing wires through metal to prevent possibility of chafing of the 25 amp feeds.

<span>I fitted the relays inside the engine bay for easy access. Mark and drill their screw holes. LH relay for the LH screen, RH relay for the RH.</span>

- Skip advertAdvertisement - Gallery continues below

<span>You’ll need two fuse holders, one for each screen feed. These fit between the battery main feed and the relays and must be rated for 25 amp capability.</span>

<span>You’ll need two fuse holders, I made a mini loom for the fuse holders to share a single terminal for connecting to the solenoid’s battery terminal, not the battery terminal direct.</span>

- Skip advertAdvertisement - Gallery continues below

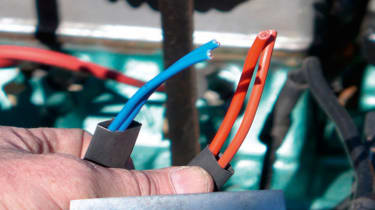

<span>Blue switch-to-relay feeds and red relay-to-screens feeds were fed through the bulkhead, then sleeved in the engine bay before fitting their terminals.</span>

<span>The screens’ negative feeds were run to each end of the dashboard beneath the parcel shelf liner tray having been heatshrink sealed first.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Black duct tape acts as barrier between the screen flat terminal feeds and bulkhead metal in the event of any chafing of wires.</span>

<span>The fully sealed connection, as done to all four screen feeds to minimise contact with metal or water in the depths of the dashboard.</span>

- Skip advertAdvertisement - Gallery continues below

<span>By refitting the fascia top temporarily, I was able to determine how the feeds should be secured under the fascia without obstructions.</span>

<span>This piggyback terminal allowed the switch feeds to both relays to connect properly and securely to the single switch terminal.</span>

- Skip advertAdvertisement - Gallery continues below

<span>The switch feed is taken from a fused 12 v feed that is not live when the ignition is off, such as a fog lamp or radio feed. This prevents battery drain</span>

<span>The switch feeds for an illuminated switch. If a separate warning lamp is used, your wiring will differ slightly.</span>

- Skip advertAdvertisement - Gallery continues below

<span><span>The negative feeds from screens and relays all go to this earthing point on the steering column bracket. Note sleeving through bulkhead grommet</span></span> <span><span> </span></span>

<span>With 25 amp fuses in the inline fuse holders, the screens were warm to the touch 30 seconds after switching on. Heated screens at last!</span>

- Skip advertAdvertisement - Gallery continues below

Recommended

Chery confirms new Liverpool HQ as plans for Jaguar Land Rover to build Chinese firm’s cars in UK gather pace

Best new cars coming soon: all the big new car launches due in 2026, 2027 and beyond

Jaguar Land Rover breaks silence on design boss Gerry McGovern exit rumours

Future of Jaguar, kill or cure? 5 huge challenges new CEO must meet to revive JLR

Most Popular

Some Chinese car brands are doomed to disappear, warns Skoda boss

New Kia EV1 electric city car on the way to rival the Renault Twingo

Meet Renault’s new SUV: a Dacia Duster but not as we know it…